Level Probes

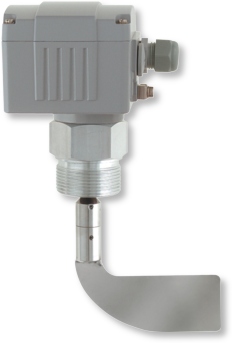

An extremely popular, low cost Rotary Paddle Level Probe.

When power is supplied to the R7z sensor a motor powers a revolving shaft to which a paddle is mounted. When the material level inside the container reaches the revolving paddle the rotation is halted and the motor rotates around the shaft and activates an isolated SPDT micro switch. This removes the power from the motor so that it stops rotating and an alarm signal is provided. When the material level falls below the paddle the motor resets and the micro switch restores the revolving action.

Features

- Available in 240VAC, 110VAC & 24VAC versions

- Reliable design

- Miniature Size

- Easy torque adjustment

- CE approved

- IP65 Rated

- Dimensions: 82mm² x 234mm high (to bottom of paddle)

- 3/4" BSP Process Connection

- Available with 4 different paddle options

- Supplied with polycarbonate paddle

The PF is a full indicator for powdery, granulated, and grainy bulk goods and preferred for mechanically filled silos and containers. The simple design enables a reliable and very price worth level indication.

Product features

- very good price-performance-ratio

- use in dust and gas explosive hazardous areas possible

- high reliability

- maintenance-free continuous operation

- easy installation

- no supply voltage necessary

- innovative protection against buckling

The VF12 is a level indicator for full, demand or empty detection in bins or silos for powdery, granulated and grained bulk goods up to a grain size of 10 mm. The very robust design allows a reliable level indication in a lot of applications.

The MFE-A is a level indicator for full, empty or demand detection of granulates and grain-shaped bulk goods with a maximum grain size of 30 mm. It is mainly used in silos, hoppers, or bins. This sensor with stainless steel membrane and aluminium housing is particularly suitable for the use in areas with dust and gas explosion hazard.

The rotary paddle level indicator DF21 is used in most bulk solids for full-, empty or demand-detection within silos and bins. The individual sensor configuration with a large number of options and a lot of accessories enables an accurate adaptation to any specific application.

The LS8000 with its remote electronics is ideal for applications where it is unsafe or inconvenient to mount the electronics directly onto the probe on the vessel.

A maintenance free epoxy- encapsulated transmitter is mounted in the explosion proof head of the probe. The receiver board can be mounted up to a mile from the transmitter, which is connected to the receiver with a twisted, shielded pair of wire. The receiver board is wired to the power supply and has all the calibration adjustments and the relay output.

Virtually any liquid, dry material or interface of electrically conductive or non-conductive product can be measured and the proprietary radio frequency (RF) balanced impedance bridge with exceptional temperature stability, eliminates the need for frequent recalibration.

The probe is made of solid 316 stainless steel rod, and the insulator is made of Teflon. The seals are made with Viton "O" rings. The transmitter electronics are housed in a cast aluminum explosion-proof enclosure.

The LS7000 is a full-featured sensor, based on the LS6000 but with onboard fuse, static and surge protection for applications like plastic pellets where static may be a problem.

A built in timer allows the user to select an ON or an OFF delay for up to 2 hours, so wave action in a turbulent vessel can be ignored or a vessel can be discharged to a lower level automatically.

Like the other probes in the Babbit range, the proprietary radio frequency (RF) balanced impedance bridge has exceptional temperature stability, eliminating the need to for annual adjustments to the calibration.

Again, all ll the necessary calibration indicators are on-board so all you need to calibrate the LS7000 is a small screwdriver. Failsafe electronics provide peace of mind and the modular nature makes troubleshooting and repair simple and quick.

The probe is made of solid 316 stainless steel rod, and the insulator is UHMWPE (Ulra High Molecular Weight Polyethylene) , which has excellent abrasion and impact resistance. The seals are Viton 'O' rings and all the electronics are housed in a cast aluminium enclosure.

The probe is made of solid 316 stainless steel rod, and the insulator is made of Teflon. The seals are made with Viton "O" rings. All the electronics are housed in a cast aluminum explosion-proof enclosure. Special materials of construction are available.

The LS6000 is a basic feature level switch, similar to the LS2000 but with more power supply choices, a second switched output and an explosion proof housing.

It incorporates the same proprietary radio frequency (RF) balanced impedance bridge with exceptional temperature stability, eliminating the need for frequent recalibration.

Like the LS 2000 all the calibration indicators are on board.

The probe is made of solid 316 stainless steel rod, the insulator is made of Delrin (Teflon and other materials optional). The seals are made with Viton “O” rings. All the electronics are housed in a cast aluminium explosion proof enclosure.

The LS2000 is a low-cost level switch that can measure virtually any liquid, dry material or interface of electrically conductive or non-conductive products. The propriety radio frequency (RF) balanced impedance bridge has exceptional temperature stability, eliminating the need to recalibrate the unit from season to season.

All the necessary calibration indicators are on-board so all you need to calibrate the LS2000 is a small screwdriver. Failsafe electronics provide peace of mind and the modular nature makes trouble shooting and repair simple and quick.

The probe is made of solid 316 stainless steel rod, and the insulator is UHMWPE (Ulra High Molecular Weight Polyethylene) , which has excellent abrasion and impact resistance. The seals are Viton 'O' rings and all the electronics are housed in a cast aluminium enclosure.

A tilt switch provides indication by detecting the angular position of the tilt switch enclosure. Typically the unit is suspended above the material to be sensed. Internally, a steel ball centres itself over a switch resulting in switch actuation. As rising material contacts the tilt switch (or the extension actuator) the enclosure begins to tilt. When the enclosure body is tilted at 17°, the steel ball rolls off centre, deactivating the switch.

As material falls away from the switch enclosure body (or the extension actuator) and the unit becomes upright, the ball returns to its original centred position, once again causing switch actuation. The change in the internal switch status is user accessible for signalling alarms, lights, or interfacing with a PLC.

Monitor's tilt switches can be used in a variety of applications and with many different types of materials. The TC-3X can be used with materials 15-60 lb/ft³, while the TC-1 can be used with materials 45+ lb/ft³.

Typical applications include:

- Feed

- Pellets

- Rubber

- Silica sand

- Wood

- Metals

- Malt

- Limestone

- Pre-mix

- Regrind

- Clays

The SafePoint fail-safe bin monitor is the state-of-the-art in rotary paddle technology. Utilising patent-pending magnetic sensing technology and a new unique housing design, the SafePoint bin monitor is the most reliable, technician friendly, rugged and economical failsafe rotary paddle point level control sensor of its kind.

The SafePoint bin monitor provides the ultimate in performance wherever critical continuous operation must be ensured. Detection of both material presence and its own operational status is performed on a continuous basis. The SafePoint level sensor monitors its electrical and mechanical operating condition. Separate outputs are provided for material sense and unit status (fault conditions).

Typical applications include:

- Resin

- Foundry Sand

- Sawdust

- Rocks

- Calcium Dust

- Regrind

- Malt

- Limestone

- Ingredients

- Cement

- Feed

The Monitor KA and KAX range of rotary paddle bin monitors consist of some of the most reliable, rugged and economical point level control sensors available for detection of dry bulk materials. These easy to install units are proven performers in a wide variety of bulk materials.

They can be used to eliminate bin overflow, maintain a predetermined material level, indicate plugging of conveyors and pneumatic lines or provide any of a number of level control functions.

Unlike many other available paddle units, the Monitor range of paddle level indicators incorporate a feature that automatically shuts off the motor of the unit when the paddle is in a stalled position, which both extends the life of the motor and minimizes maintenance.

The KA model is the most popular for standard applications on a wide variety of materials. The KAX version is specially designed to meet hazardous area standards.

Typical applications include:

- Feed

- Pellets

- Rubber

- Coal

- Clays

- Grain

- Rawhide

- Silica Sand

- Wood

- Metals

- Peanuts