Industrial Weighing

- Range - 1 kg/hr up to 200 t/hr

- Turndown - Normally 10:1 with up to 100:1 in certain applications.

- Accuracy - Typically 0.25% of Set Rate.

Options

- AC or DC variable speed drive units.

- Conditioning/ agitating section for difficult materials.

- Dust-tight enclosures.

- Metering screw, belt, vibratory feeder or pump discharge.

- Food quality finish in mild steel or stainless steel to F.D.A standards.

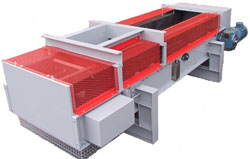

The Golconda range of weigh belt feeders has been designed to extract and convey materials to preset feed rates with accuracies typically +/- 0.5% over 10:1 turndown. Standard feeders are available with belt widths from 600 mm to 1500 mm and suitable for feed rates between 0.5 and 1500 tonnes per hour.

Although we have standard ranges our feeders are generally tailor made to suit the clients’ requirements. The Golconda weigh belt feeder combines the versatility, precision, and reliability of PLC technology with high quality mechanical design and construction.

Dynamic weighing on a troughed belt requires understanding and experience. At Golconda we have both. Golconda’s belt weighers range from simple single / twin idler units for general purpose low accuracy (+/- 2%) applications to larger four /six idler systems where greater accuracy is required (+/- 0,5%).

The belt weighers are suitable for both horizontal and inclined conveyors. They are easy to assemble and install and, as they have a high degree of reliability, have minimal maintenance requirements. Capacities range from 250 kg/hr to 6000 t/hr.

The PLC based belt weigher module is reliable, accurate, and easily programmed.

Golconda’s engineers are experienced at providing bespoke weighing systems for customer’s own specific projects. Selecting the most appropriate proprietary load cells we can engineer the mountings where required or offer advice if necessary.

We provide the power supplies, amplifiers and instrumentation to make use of the weight signal in a process control application or simply for silo level control.

The photograph shows a stainless steel mixing vessel weighed using four xyz load cells with custom made mounting assemblies allowing the vessel to move under thermal expansion and contraction but to eliminate non axial loading.

This application was for a series of vessels in a chemical processing plant.